- At on-site or source where product is manufactured and sometimes at forwarder’s premises.

- At the stage when 100% production is completed and at least 80-85% goods are completely packed in cartons and ready for shipment.

This Inspection is conducted on the standards of internationally recognized ANSI/ASQC Z1.4-2008 (Equivalent to MIL-STD-105 E, ISO 2859) statistical sampling procedures.

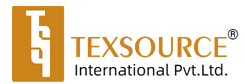

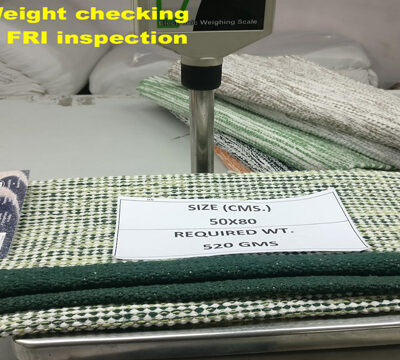

The Final Random Inspection covers various aspects of the production; (Refer techniques page for details).

All these inspections are carried out in an accurate and detailed manner by experts who are having knowledge in products and inspection techniques. The actual findings during the Inspection are marked in the RSJ detailed report and sent to the customer within 24 working hours for their final decision on the shipment.

Your Ears & Eyes in the Factory

The report of Final Random Inspection mentioned with the findings of all aspects of product quality in a detailed manner helps customer to view the product standards from their place instead of travelling or visiting the manufacturing country/ locations in order to understand the goods produced are up to the customer remarks.